Precision Optical Low-Coherence Reflectometry for Fiber Testing

Fiber Optical Test provide industry-grade OLCR systems that meet the most demanding inspection requirements.

Overview

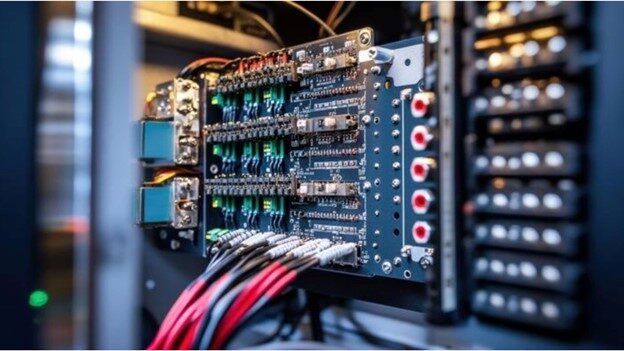

Optical Low-Coherence Reflectometry (OLCR) is an advanced testing technique that uses low-coherence interferometry to measure optical path differences and locate faults or structural variations within fiber optic components. Unlike traditional reflectometry, OLCR delivers exceptional spatial resolution and is ideal for characterizing short optical devices or layered structures. At Fiber Optical Test, we provide industry-grade OLCR systems that meet the most demanding inspection requirements. Headquartered in Grand Chute, WI, we’ve earned recognition across North America for delivering highly reliable, forward-thinking fiber testing technologies. Through rigorous R&D, quality assurance, and customer-first service, we empower B2B clients to achieve high-performance diagnostics, increased operational efficiency, and long-term system reliability.

Core Components of Optical Time-Domain Reflectometry

Hardware

- Broadband Low-Coherence Light Sources – Essential for generating wide spectral bandwidth, enabling precise axial resolution. (Related: Wi-Fi HaLow End Devices for wireless diagnostic access.)

- Fiber-Coupled Interferometers – Provide precise distance measurement and depth profiling in fiber assemblies. (Related: Zigbee End Devices for integrated fiber alignment control.)

- High-Dynamic Range Detectors – Capture subtle back-reflections from layered fiber structures. (Related: UHF RFID Readers, Tags & Accessories for tagged fiber tracking.)

- Compact Modular Platforms – Scalable configurations for lab, production, or field deployment. (Related: On Premise Edge for localized real-time processing.)

Software

- Spectral Interference Analysis Tools – Extract spatial and spectral data for detailed diagnostics.

- Auto-Calibration Modules – Ensure optimal system accuracy and repeatability.

- Interface Control Software – Manage acquisition parameters, data visualization, and export workflows.

Cloud Services

- Remote Monitoring Dashboards – Real-time observation and trend logging of OLCR scans across sites.

- Cloud Archive & Retrieval – Centralized scan data storage with instant search and download functionality.

- Version-Controlled System Updates – Receive regular firmware and software improvements.

Key Features and Functionalities

Integrations and Compatibility

- Interfaces with robotic fiber handling units

- Compatible with photonic device inspection lines

- Works with standard optical alignment systems

- Compatible with SMF, MMF, and integrated photonic circuits

- Supports major data formats (CSV, HDF5, MAT)

- API support for Python, C++, and LabVIEW environments

Applications

- Quality control of fiber-optic transceivers

- Reflective coating analysis in optical components

- Embedded sensor diagnostics

- Biomedical imaging probes

- Micro-optic component assembly validation

Relevant U.S. & Canadian Industry Standards and Regulations

- Telcordia GR-2923

- ANSI/TIA-455 series

- IEEE 802.3

- ISO/IEC 11801

- CSA C22.2 No. 182.2

- Micrometer axial resolution over short optical paths

- Accurate reflection mapping of optical components

- Non-invasive, non-destructive fault detection

- Ideal for multilayer and short-length fiber diagnostics

- Real-time spectral-domain analysis

Benefits

- Pinpoint micro-reflections and discontinuities

- Reduce QA cycle time and improve manufacturing yield

- Extend component reliability by detecting early-stage failures

- Lower service downtime with preemptive diagnostics

- Enhance traceability with digital scan logging

Industries We Serve

- Fiber Optic Manufacturing

- Biomedical Device Engineering

- Aerospace and Avionics

- Telecommunications R&D

- Academic Research Labs

Case Studies

Case Study 1 (U.S.)

An avionics manufacturer in Florida used Fiber Optical Test’s OLCR systems to analyze micro-reflective events in shielded fiber bundles. This improved inspection precision by 35%, helping meet stringent aerospace reliability standards.

Case Study 2 (U.S.)

A medical imaging company in Minnesota deployed our OLCR solution to test fiber-based endoscopy probes. The system’s high resolution revealed structural delamination early, reducing product failure in clinical trials by 22%.

Case Study 3 (Canada)

An Ontario-based fiber component supplier integrated Fiber Optical Test’s OLCR units into their inline QA process. After deployment, defect detection efficiency increased by 41%, boosting their global shipment reliability metrics.

ave questions or need support with your fiber optic testing needs?

Our team is here to help.

Get in touch with Fiber Optical Test today by visiting our Contact Page

Whether you’re seeking technical advice, product recommendations, or a customized solution, we’re ready to guide you every step of the way.